High performance fiber materials have the characteristics of low density and high strength. It has a certain degree of corrosion resistance and can be used for the manufacturing of rocket engine shells, as well as structural components such as the fuselage, main wing, and tail wing of aircraft and spacecraft.

High performance fiber materials are lightweight and wear-resistant. After being made into accessories such as phone cases and flat cases, they are lighter in weight, more wear-resistant and scratch resistant compared to traditional materials, and have better protection.

High performance fiber materials are mainly used in the transportation field to manufacture automotive interior materials, including car door panels, operation consoles, tires, seats, etc.

High performance fibers have low density, light weight, high strength, and good protective performance. It is widely used in bulletproof vest, bulletproof helmets, explosive discharge clothing in the field of personal protection, as well as bulletproof body and armor plate in the field of vehicle protection.

High performance fiber materials have the characteristics of good weather resistance, low density, high strength, and good protective performance, and can be widely used in the field of sports equipment, such as surfboards, snowboards, bicycles, etc

XINXIU New Materials was established in 2009, which is one of the high-tech enterprises in China. XINXIU focuses on the development and application of high-performance composite materials, and is committed to breaking the blockade of high-performance materials. Providing one-stop solutions for composite material design/production/testing.

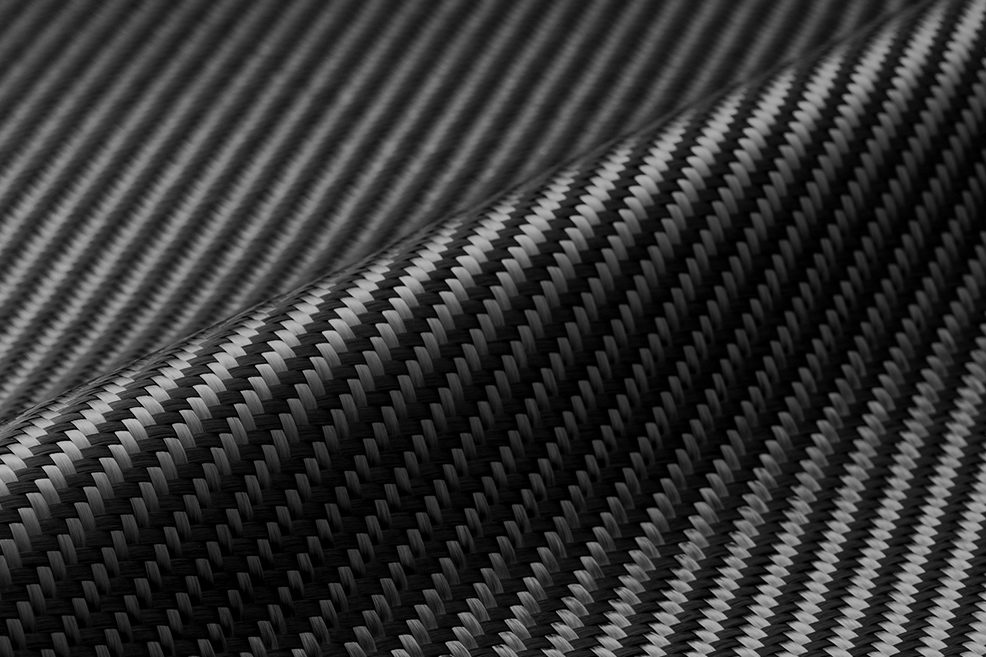

Carbon fiber is widely used in the field of lightweight materials, such as aerospace, protective equipment, fishing gear, sports equipment, and sports equipment.

Alumina continuous fiber is a high-end material of special refractory products. It has excellent high temperature resistance, corrosion resistance, low deformation and unique electrochemical properties. It can be used in high temperature environment above 1000 ℃ for a long time.

Aramid fibers have superior resistance to heat, low flammability, and high resistance to organic solvents. They have been used extensively in body armor, vehicle armor, military helmets, protective gloves, and fireproof suits for firefighters.

Showcell fiber is manufactured by dissolving cellulose in a green solvent to obtain the solution, which was precipitated into the coagulation bath. The spinning process is a physical process with the closed circulation, coagulation and dissolution. It is a "truly green and environmentally friendly fiber".

Flax fiber is the strongest fibers among natural fibers, which is the first stem fibers used by human. It has good mechanical strength, good sound absorption performance, and excellent shock absorption performance.

The company belongs to the high-tech enterprises, specialized and special new enterprises. XXINXIU focuses on the development of natural fiber composites, the secondary design and reprocessing of synthetic fibers, and independently researches and develops a variety of different resin-based formulas to meet the needs of customers for different product properties. Will be in the new materials industry, fine-tuning, continuous innovation.

XXINXIU has 4 production bases in Dongguan, Changzhou, Guangxi and Vietnam, and will set up XXINXIU New Material Research Institute in 2023 to provide a full set of solutions for composite material design, R&D, production and testing, with a focus on customers.

The company has more than 80 technical personnel, formed into an international industry cutting-edge R & D team, with strong R & D strength, with the ability to continue to innovate, for product development, transformation, upgrading to provide a reliable guarantee, the company has 18 patents of invention and 7 utility model patents; the company has 33 trademarks, the formation of a relatively complete property rights protection system.

The company has 18 invention patents and 7 utility model patents, the company has 33 trademarks, forming a relatively complete intellectual property protection system.

The company belongs to high-tech enterprises, specialized and special new enterprises, with OHSAS, ISO, SA, FSC, SGS and other perfect quality assurance system.

Common racket frame materials on the market are: carbon fiber, fiberglass, aluminum alloy, magnesium aluminum alloy, iron, steel, bamboo and wood. The second is the visual method, see if there is a black layer near the part of the racket face, whether there is a micro-sawtooth, aramid fiber fabric is relatively thin, and the warp and weft of the weave, after sawing naturally have a micro-sawtooth.

Highly recommended by foreign media - the most innovative e-bike in 2021Powerful, outstanding performance, unique designThis is the future of e-bikes. Technology combines carbon fiber and aramid fiberHigh-end carbon fiber bikes are highly popular in the market. Provide a comfortable and enjoyable riding experienceSafety first, comfort first.

From March 6 to 8, 2018, the 53rd JEC International Composites Exhibition in France, was successfully held in Paris, France. Xinxiu New Material Booth Carbon Fiber Car Hood Glass Fiber New Energy Vehicle Battery Cover Carbon Fiber Luggage, Carbon Fiber Fishing Box Part of Smart Home Products Part of 3C Products (Forged Carbon, Ceramics and other new materials)

At 10:00 a.m. on August 29th, along with the pouring of the last concrete in place, in the sound of festive salutes, Xinxiu ushered in a brilliant moment with milestones - Xinxiu new materials capital expansion project project glory topping. We would like to express our sincere condolences to the construction workers who worked hard for the construction of the building!

Common racket frame materials on the market are: carbon fiber, fiberglass, aluminum alloy, magnesium aluminum alloy, iron, steel, bamboo and wood. The second is the visual method, see if there is a black layer near the part of the racket face, whether there is a micro-sawtooth, aramid fiber fabric is relatively thin, and the warp and weft of the weave, after sawing naturally have a micro-sawtooth.