Innovation

The company is a high-tech enterprise, a specialized and new enterprise, a research and development center co built by the Yangtze River Delta Carbon Fiber and Composite Materials Technology Innovation Center, and has a number of joint research and development projects with Donghua University, Wuhan University and other universities. Focusing on customers, the company provides a full range of solutions for composite material design, research and development, production and testing

Our Vision

Becoming the world's best composite material product solution company

-

18

Invention Patent -

8

Practical Patent -

33

Trademark -

10%

R&D Investment

Patent

-

Product Features

Product FeaturesRenewable and biodegradable fibers;

Green manufacturing process;

Excellent mechanical property;

Has good affinity with resin.

-

Product Qualification

Product QualificationThe company has 18 invention patents and 7 utility model patents; The company owns 33 trademarks;

10% of the company's annual revenue is invested in research and development;

Co construction of R&D Center for Carbon Fiber and Composite Materials Technology Innovation in the Yangtze River Delta;

It has a number of joint research and development projects with Donghua University, Wuhan University and other universities.

-

Application Industry

Application IndustryFibers have been widely used in various industries such as aerospace, protective equipment, consumer electronic structural components, and sports equipment due to their excellent mechanical properties, high strength, high elastic modulus, corrosion resistance, high and low temperature resistance, and fatigue resistance.

Intelligent Manufacturing

The composite material laser cutting machine independently developed by Xinxiu New Materials is suitable for melting, cutting, and drilling fiber reinforced composite materials. The heat affected zone is small and does not damage fibers, which is high-speed and high-quality. At the same time, we have independently developed Rapid prototyping equipment with independent intellectual property rights for rapid heating and rapid cooling. This technology is dedicated to mass production and is a great processing solution for thermosetting and thermoplastic materials. Especially for fiber reinforced thermoplastic composites, rapid heating and cooling equipment is an indispensable equipment for mass production. In addition, Xinxiu New Materials has independently developed various equipment such as loading and unloading robots, polishing and polishing robots, automatic cloth pasting machines, and automatic composite material cutting for use in injection molding machines and hot presses.

-

Automation Moulds

Automation MouldsVarious imported high-precision moulds and processing test equipment, including Germany Demagi DMG, Japan Makino MAKINO, slow-feeding wire cutting wedm-ls, EDM EDM, etc., for high-precision moulds and parts processing. More than one hundred people R&D mould room; Plastic mould processing monthly capacity of 15 sets; Fixture processing capacity of 150-200 sets.

-

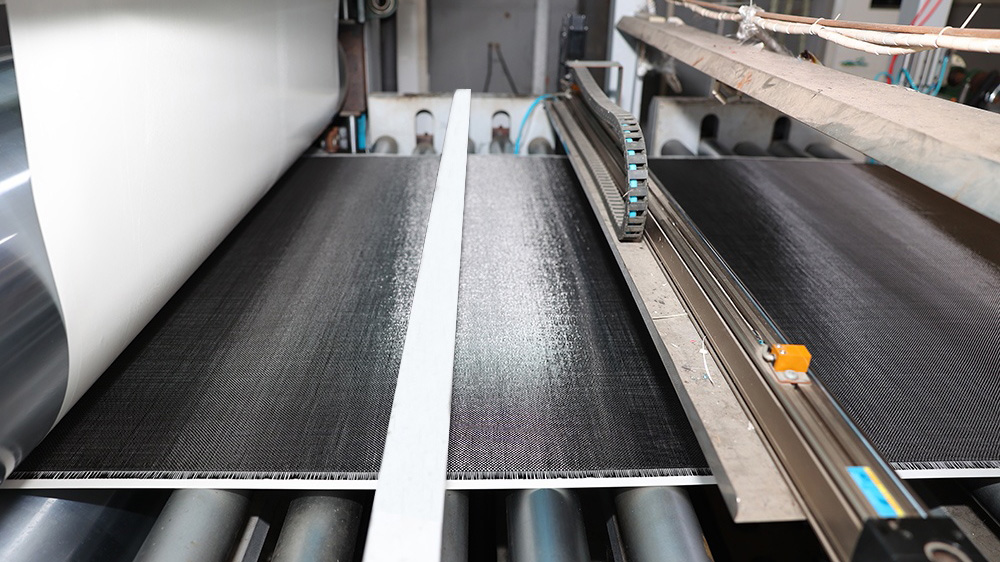

Prepreg line

Prepreg lineMultiple prepreg lines

-

Fully Automatic Painting Line

Fully Automatic Painting LineThrough the construction of intelligent facilities, in the enterprise production process, more comprehensive refinement, customised production management significantly provide the efficiency of the automation project at all stages

-

Die casting moulding line

Die casting moulding lineThrough the construction of intelligent facilities, in the enterprise production process, more comprehensive refinement, customised production management significantly provide the efficiency of the automation project at all stages